Iron ore pellets and Pelletizing processes |

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh ...

WhatsApp)

WhatsApp)

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh ...

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals ...

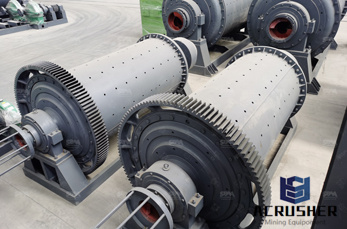

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

The perfect size rubber broom for cleaning at home. Can also be ideal for light duty cleaning at the office, hair salon or pet groomers. The unique head with pliable ...

Chapter 93. Construction HEALTH AND SAFETY HAZARDS IN THE CONSTRUCTION INDUSTRY. James L. Weeks. Construction workers build, repair, maintain, renovate, .

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Reliable Pipes Tubes Ltd., API PIPE SUPPLIER, API 5L GR B PSL2, API 5L X60 PSL2, API 5L X65 PSL2, API 5L X65,

''A'' series of paper sizes Arækkens papirformater (DIN) abbreviate (fx et ord) forkorte abecedarian (adj.) alfabetisk ordnet (også) aberration (fejl ...

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

The AESSEAL ® FLOWTRUE™ is a fully patented flow control device. The product range is specifically designed to allow the FLOWTRUE™ to be used with packed glands ...

This series of installments from David Ball''s excellent "Baseline" column discusses the relevance of quantum mechanics for spectroscopy and why it is important ...

Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. b) CNC program simulation and gcode debugger ...

When it comes to small cement projects like implanting a fence post, mailbox, or even doing minor driveway repairs, you''d be surprised how easy it is to use ready ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Primary Considerations. Businesses and establishments that require forklifts address several issues before making a purchase. To avoid size problems, the diameter ...

Burning in a kiln – formation of cement clinker. The next step in the process is to heat the blended mixture of raw ingredients (the raw mix) to convert it ...

Design features of rotary cement kilns ... Riveted construction continued until WWII. The technique of making welded joints in such heavy plate by arc welding ...

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

From DIY instructions for home improvement projects to design inspiration for your home, eHow offers all the essential howto info you need.

Advantages of coal based thermal Power Plant. They can respond to rapidly changing loads without difficulty; A portion of the steam generated can be used as a process ...

Two of the most commonly specified requirements for concrete used in the manufactured concrete products industry are the design compressive strength (f'' c) and the ...

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

See All Homework Questions here. Experts List : 1: P191 P195 P201 P207 P208 : 2: E511 Kelly Corporation at Dec

WhatsApp)

WhatsApp)